Exploring Corrugated Cardboard Flutes, Their Sizes, and Diverse Applications

When you think of cardboard, you might picture a single, flat sheet of material. However, corrugated cardboard, the sturdy material often used for packaging, shipping boxes, and even creative DIY projects, is more complex than meets the eye. At the heart of corrugated cardboard’s strength and versatility are its “flutes,” which come in various sizes and have distinct purposes. In this article, we’ll delve into the world of corrugated cardboard flutes, exploring their sizes and the wide array of applications they serve.

Understanding Corrugated Cardboard

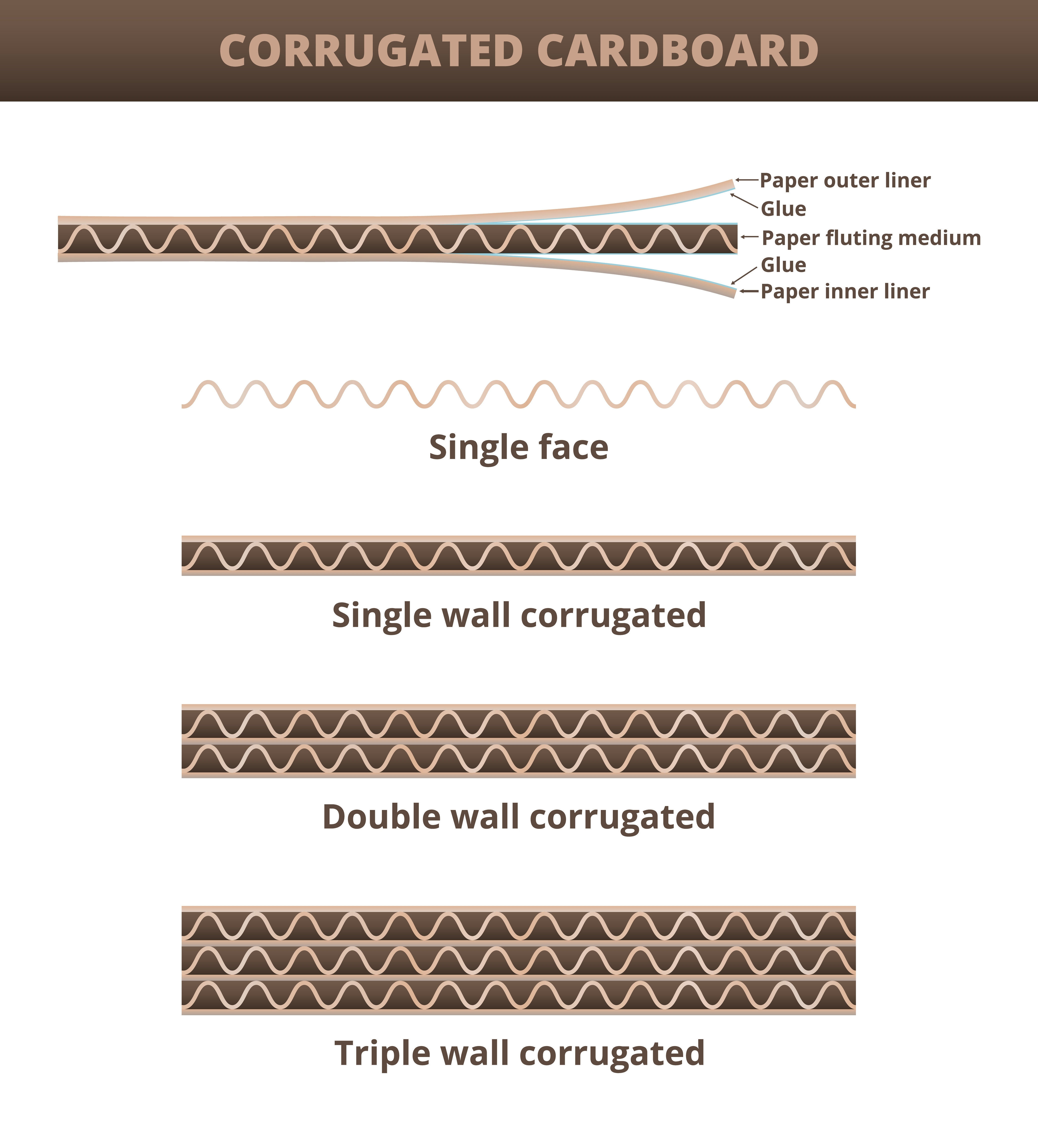

Before delving into flutes, let’s understand corrugated cardboard itself. It consists of three primary components: two flat linerboards and a wavy or pleated inner layer known as the corrugated medium. The flutes are responsible for providing rigidity, strength, and cushioning to the cardboard structure.

Different Flute Sizes

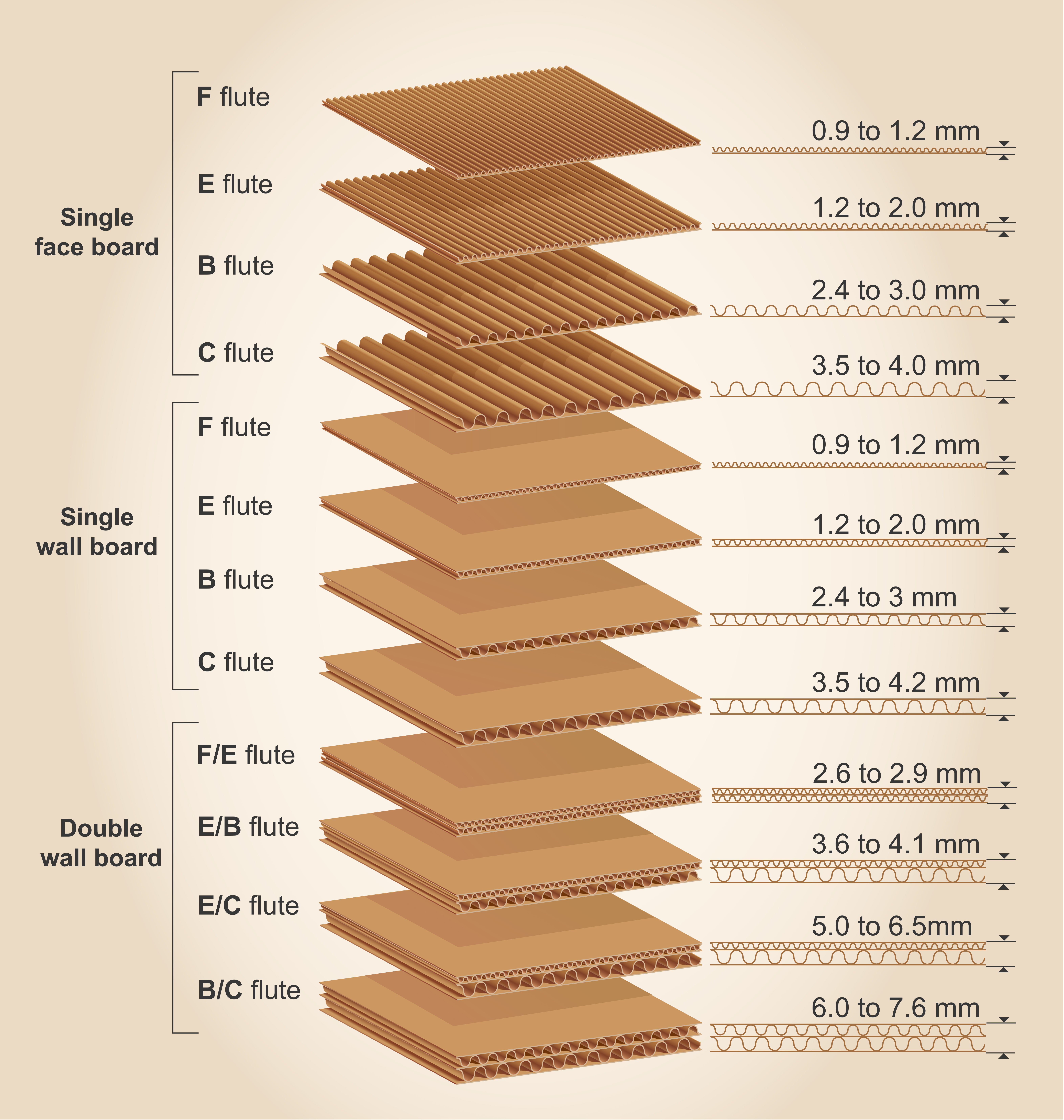

Corrugated cardboard comes in various flute sizes, each with its unique characteristics and applications. Here are the most common flute sizes:

- A-Flute (5mm): A-flute is the largest and the most common flute size. It provides excellent cushioning and shock absorption, making it ideal for protecting fragile or delicate items during shipping. Its thickness also offers strength for stacking, making it suitable for heavy-duty applications.

- B-Flute (3.2mm): B-flute is thinner than A-flute but still provides good cushioning and stacking strength. It’s often used for retail packaging, point-of-sale displays, and die-cut boxes due to its smooth surface and printability.

- C-Flute (4mm): C-flute strikes a balance between A and B-flutes. It offers adequate cushioning and strength and is commonly used for a wide range of applications, including shipping boxes, storage containers, and displays.

- E-Flute (1.6mm): E-flute is the thinnest of the commonly used flutes and is known for its fine texture and exceptional printability. It’s often used for high-quality retail packaging, custom boxes, and specialty applications where a clean and polished appearance is desired.

- F-Flute (0.9mm): F-flute is even thinner than E-flute and is designed for applications requiring intricate die-cutting and folding. It provides a lightweight yet sturdy solution and is frequently used for small retail boxes and displays.

Applications of Different Flute Sizes

Now that we’ve explored the various flute sizes let’s delve into their diverse applications:

- A-Flute: A-flute is typically employed for heavy-duty packaging, such as shipping fragile electronics, ceramics, or glassware. Its thickness and shock-absorbing properties protect delicate items during transit.

- B-Flute: B-flute is often used for retail packaging, including shoeboxes, cosmetics, and small appliances. Its printability and smooth surface make it ideal for showcasing branding and graphics.

- C-Flute: C-flute’s versatility makes it suitable for various applications, from shipping boxes for books and consumer goods to storage containers and displays.

- E-Flute: E-flute’s fine texture and printability make it a popular choice for custom boxes and high-end retail packaging, especially for products like chocolates, cosmetics, and electronics.

- F-Flute: F-flute’s thinness and flexibility are perfect for intricate designs and die-cutting. It’s often chosen for small, lightweight packaging and unique shapes.

Double Wall

Now that you’re familiar with the different corrugation sizes, we can take cardboard, one step further: Double Wall. This is when two (usually) different flute sizes are used in one piece of cardboard. This creates a package, or in our case a sled, with the best qualities of each flute size. For instance, an EB Double Wall will offer the best printability of the E flute with the strength of the B Flute. Understanding these flutes empowers businesses and creative minds alike to choose the right cardboard structure for their specific applications, ensuring both functionality and aesthetic appeal in their projects.